users can add new sensor type oil pump, and a pressure sensor for different display value recalibration.provide Bosch, pre-calibrated value Delphi, Denso, JIER rail pressure sensor.The system can also be extended, such as centralized management of multiple devices, unified data reporting, especially for common rail device manufacturers batch testing.

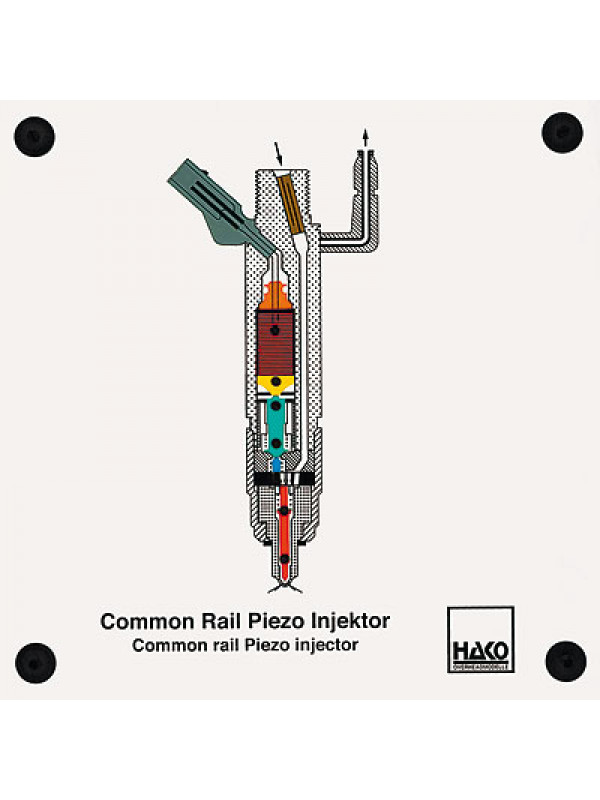

#Piezo injector testing borders driver

In addition the device driver parameters can be flexibly adjusted to suit the pump and injector testing special models, ease of maintenance personnel working status Common Rail System judge and maintenance. 2.2 Product FeaturesĬRS960 common rail control system components can be flexibly matching, to form different control platforms to meet the functional, cost, size, and many other needs, to achieve the highest price.

Wide range of equipment, can be widely measurement Bosch, Denso, Delphi, Siemens and other common rail pump and injector, the injector system is equipped with more than 1600 injectors data, in maintenance and inspection can be used as a reference value or reference value, allowing users repair work more convenient. Regular replacement of diesel fuel and oil tank filter road.ĬRS960 (Common Rail System CRS960) common rail control system by controlling the operation of the common rail test bench to complete the common rail pumps, common rail injector, high-pressure fuel rail test.The device is placed in a dry, airy, sun, less dusty environments.Also need regular long idle power operation, to ensure controller's internal circuitry is not damp.Unplug the power cord when cleaning the test bench, the device needed to be clean to boot after drying.Avoid walked on or pinched AC power cord.Do not allow dust or foreign matter accumulate around the terminal of AC power, the accumulation of dust on the AC terminals and foreign matter may cause a fire or electric shock.Do not touch the cable terminal with wet hands.Do not allow water or other liquid into the controller.Do not put foreign objects into the internal test bed.Do not throw, drop or treading bench, avoiding the controller by a strong external impact.If the control system fails, please contact the service personnel to obtain the necessary assistance.The controller working environment temperature required between 0-35 degrees Celsius, and ensure good ventilation, avoid long hours working.If the controller abnormal situation, or an abnormal sound or smell, smoke, please stop using the device and turn off the power guillotine.Be sure to plug in the connector plug operation shut down and turn off the power of the state, to avoid damage to static electricity or other external controller.Regularly check the AC power cord is damaged, and whether the power plug or power outlet dust accumulation.

Run conditions were found to have leaks should immediately stop processing, and then test to find out why and rectification

0 kommentar(er)

0 kommentar(er)